| Multi-Scale Alignment and Positioning System (MAPS) | |

|

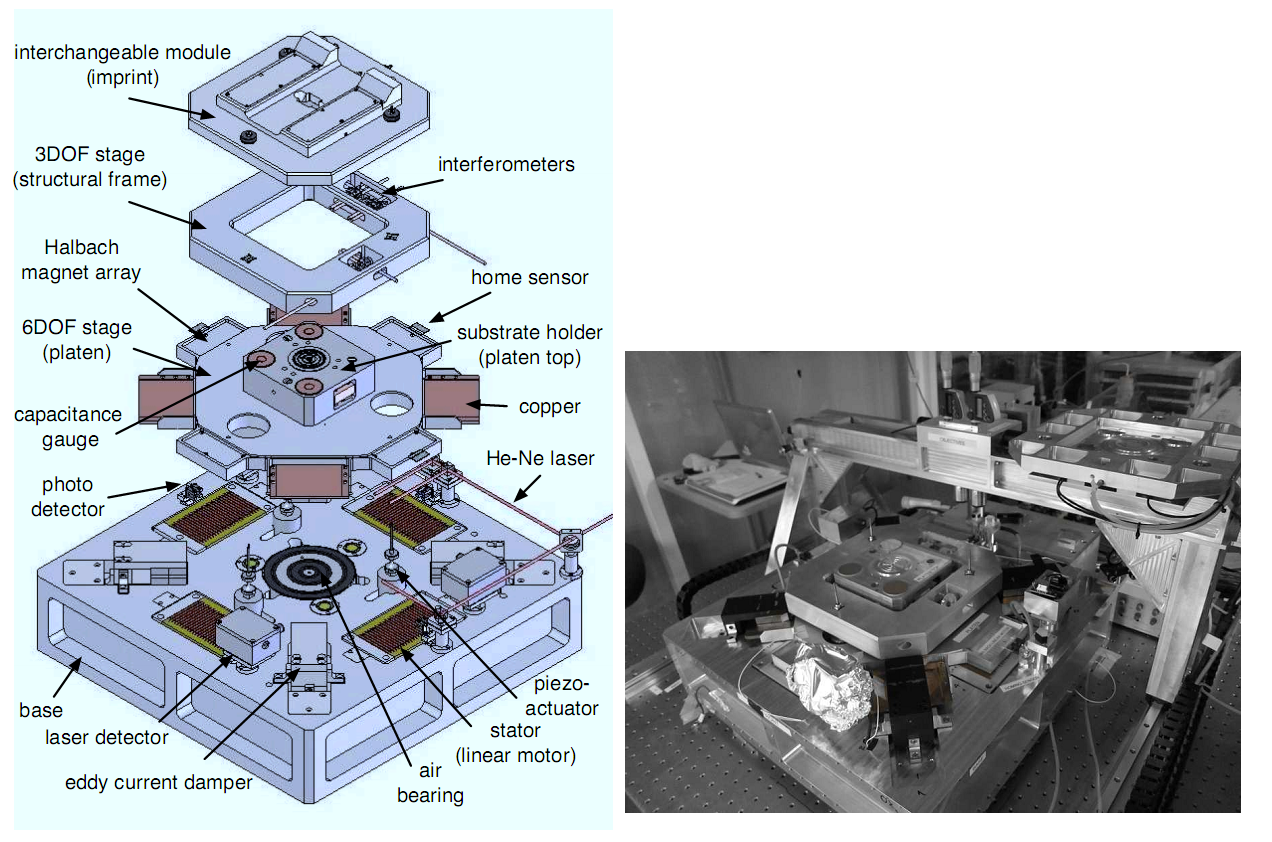

Engineers in the NSF SINAM Center have designed and built a Multi-Scale Alignment and Positioning System (MAPS) for precision engineering. MAPS represents the culmination of 3 years work of an interdisciplinary and collaborative team. MAPS addresses a critical problem of industrial nanomanufacturing: how to scale production of nano-scale components with macroscopic scale tools. MAPS is currently a test-bed that provides 5 nm precision over distances of 2 inches, which is more than 5 million times larger than the maximum precision. MAPS consists of a precision positioning stage, control system, and a series of interchangeable modules. The modules allow the system to be easily adapted to the various nano-lithography and nano-characterization techniques being developed by SINAM. Control of the system is critical to achieving high-speed and dynamic precision in step-and-scan and continuous scan motion. State of the art control software has been developed to allow fast scanning at the required precision. Another critical issue is thermal expansion caused by the heat generated by the linear motors. MAPS has been designed to limit thermal deformation to sub 1 nm scales. |

|

|

|

Researchers:

|

|

Related Publications:

|

|